Why Measuring Slip Resistance Properly Matters

At first glance, slip resistance seems easy to measure: apply a downward force on the shoe (the Normal Force), push it sideways (the Horizontal Force), and calculate the ratio—the Coefficient of Friction (COF). Simple, right?

The reality is very different. The moment you introduce a contaminant—like water—the physics change dramatically. That thin film acts as a lubricant, and how it behaves depends on the dynamics of the contact: speed, angle, rotation, and force.

To replicate the conditions that actually cause people to slip and fall, a test must capture these complex, real-world lubrication effects. The challenge of measuring slip resistance in a meaningful way isn’t trivial—nor are the implications of getting it right-it’s the difference between numbers on a page and genuine injury prevention.

The history of footwear slip testing

-

The earliest widely used method of measuring slip resistance was the ramp test. In principle, it’s beautifully simple: a person walks back and forth on a sample surface while the ramp angle is gradually increased until they slip. From a dynamics point of view, it’s hard to beat—real human gait, real motion, and realistic lubrication effects.

The problem? It’s expensive, time-consuming, and not especially practical—particularly in high-wage economies where the cost of running human-based tests is prohibitive. That’s why, despite its accuracy, ramp testing is relatively rare outside a few specialist labs.

This gap between realistic dynamics and practical testing set the stage for the development of mechanical slip testers—tribometers—which attempt to replicate the critical conditions of slipping without needing a human to risk a fall.

-

Since the ramp test is good but unscaleable, slip testing has diverged into two streams:

Flooring Tribology

The pendulum test emerged as a practical alternative. Compact, reproducible, and cost-effective, it captures the critical physics of contaminated surfaces well enough to become the global benchmark for floor slip resistance.Footwear Tribology

For shoes, the story is different. Attempts to mechanise gait led to the development of the test method now enshrined in ISO 13287. While it is widely adopted, the method has well-known shortcomings. It does not convincingly reproduce the complex physics of real human slipping—factors such as contact speed, rotation, angle, and loading are poorly represented. Even its consistency is questionable: repeatability is limited, reproducibility is worse, and manufacturers are known to resubmit identical shoes in the hope of securing a pass after a previous failure.

-

The limitations of ISO 13287 have left footwear testing without a method that truly reflects the conditions under which people slip. This is where the Neospire® SoleXT steps in.

Building on the proven dynamics of the ramp test, SoleXT faithfully replicates the key elements of human gait—heel strike, loading, rotation —under controlled laboratory conditions. By recreating the way shoes actually interact with contaminated floors, it delivers measurements of slip resistance that are not just numbers, but indicators with real-world meaning.

The result is a step-change in footwear tribology: a test method that is scientifically rigorous, practical to deploy, and—most importantly—aligned with the conditions that lead to actual slips and falls.

With SoleXT, manufacturers and test labs can finally generate slip resistance data that carries real utility for product development, compliance, and injury prevention.

-

The Health and Safety Executive’s GRIP scheme was a landmark initiative, providing the UK’s first independent, evidence-based slip resistance ratings for footwear. Developed with input from industry and academia, it translated complex tribology into a simple star rating that employers could trust. Shoes rated GRIP 3, 4 or 5 consistently reduced the risk of slips and falls, while lower-rated footwear carried higher risks. The scheme was widely recognised as one of the most practical and effective safety interventions of its time.

Kevin Hallas, now founder of Neospire, played a central role in creating GRIP while at HSE. It was, in many ways, his baby — designed to bridge the gap between laboratory testing and real-world safety. GRIP offered exactly what workplaces needed: clarity, independence, and a strong scientific foundation.

But GRIP was built on the German ramp test method, which required human operators to walk repeatedly on contaminated surfaces while the ramp angle was slowly increased. While scientifically valid, this approach was eyewateringly labour-intensive, expensive, and slow, with capacity for only a limited number of tests each year. That meant footwear manufacturers and employers could not always access ratings at the scale the market demanded. Over time, the resource burden proved unsustainable, and HSE eventually stepped back from running the scheme. Its disappearance has left a clear gap: without GRIP, employers no longer have a trusted benchmark for choosing safe footwear.

-

At Neospire, we see the gap left by GRIP every day — and we are determined to fill it.

With the SoleXT tribometer now validated in the largest RCT of its kind (the SSHEW Study), we have the technology, expertise, and evidence base to build a next-generation scheme. Unlike the ramp, SoleXT delivers high-fidelity, repeatable measurements without the bottlenecks of human operators.

Our aim is to honour the strengths of GRIP while going further: combining rigorous laboratory testing, advanced measurement techniques, and real-world validation to create a rating system that is scientifically robust, practical for industry, and sustainable at scale.

More on how we know the test is valid…

A test method is only useful if it predicts what happens in the real world. The Neospire® SoleXT has been put to that test through the SSHeW Study (Stopping Slips among Healthcare Workers) — the largest randomised controlled trial (RCT) of its kind.

Over 4,500 NHS staff took part, with footwear allocated on the basis of laboratory slip resistance ratings. The outcomes were clear and striking:

A 63% reduction in slips

A 51% reduction in falls

Crucially, the slip resistance of the footwear in both arms of the trial was measured using the SoleXT tribometer. That means the reductions seen in real workplaces directly validate the test: when SoleXT predicts higher slip resistance, people really do slip less.

The footwear assessments tell the same story. In the control group, almost 90% of shoes tested were poor performers (GRIP <3), while in the intervention arm every shoe was rated GRIP ≥3. The results matched perfectly: the only slips recorded in the intervention group were when staff failed to wear the provided footwear. In other words, the SoleXT ratings not only predicted laboratory performance but directly explained the observed safety outcomes in the trial.

The implications are substantial. Slip and trip claims have cost the NHS more than £126 million in the last decade, averaging over £12 million per year in damages and legal costs. By contrast, the intervention footwear prevented slips altogether — a change that would more than pay for the investment in safer shoes.

This is rare in the world of tribology: direct evidence from a gold-standard RCT linking laboratory measurement to real-world injury outcomes. It gives SoleXT a uniquely strong claim. Not only does it replicate human slipping dynamics with scientific precision, it has been proven to predict and prevent accidents in practice — delivering measurable safety benefits and real financial savings.

Passing the Reins: From Research to Real-World Impact

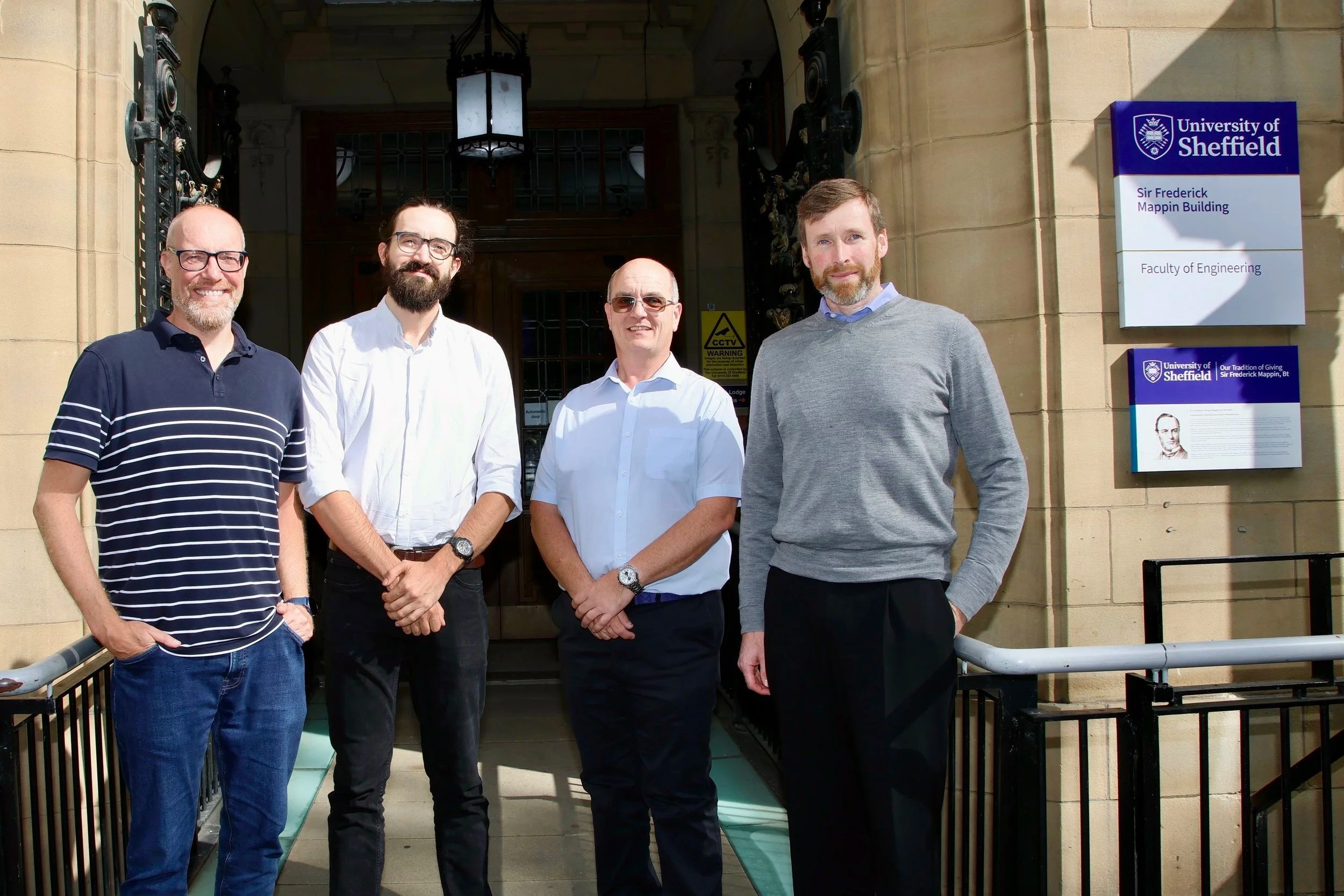

In September 2025, Neospire Limited signed a Licence Agreement with the University of Sheffield to take forward their footwear slip testing machine. This marks an exciting new phase: transferring proven academic research into practical use for industry.

The technology was pioneered by Professor Matt Carré and his team at the University of Sheffield, in collaboration with Mark Liddle and colleagues at the Health and Safety Executive (HSE) where Kevin was the Technical Lead for Falls Prevention. Our contract was expertly steered by Sam Trotter, ensuring a smooth transition from university IP to commercial application.

The collaboration has deep roots. Kevin Hallas, now Founder of Neospire, first met Professor Carré back in 2003 while working at HSE’s Laboratory in Sheffield. A chance conversation about footwear and surface interactions sparked a partnership that has endured for over 20 years.

Today, that same spirit of collaboration underpins Neospire’s mission: to use rigorous testing and practical insight to reduce slips, trips, and falls. By commercialising the footwear slip testing machine, Neospire will provide manufacturers, buyers, and safety professionals with access to world-class research translated into real-world solutions.

As Mark Liddle put it: “I’m excited that something is going to happen with the technology and the impact that will have on people’s safety.”